YXC75B Series

YXC75B Series Rated Capacitance Table

Code | Cap. pF | Tol. | Rated WVDC | Code | Cap. pF | Tol. | Rated WVDC | Code | Cap. pF | Tol. | Rated WVDC | Code | Cap. pF | Tol. | Rated WVDC |

0R5 | 0.5 | A B C D | 500V | 3R3 | 3.3 | A B C D | 500V | 240 | 24 | F | 500V | 181 | 180 | F | 300V |

0R6 | 0.6 | 3R6 | 3.6 | 270 | 27 | 201 | 200 | ||||||||

0R7 | 0.7 | 3R9 | 3.9 | 300 | 30 | 221 | 220 | 200V | |||||||

0R8 | 0.8 | 4R3 | 4.3 | 330 | 33 | 241 | 240 | ||||||||

0R9 | 0.9 | 4R7 | 4.7 | 360 | 36 | 271 | 270 | ||||||||

1R0 | 1.0 | 5R1 | 5.1 | 390 | 39 | 301 | 300 | ||||||||

1R1 | 1.1 | 5R6 | 5.6 | 430 | 43 | 331 | 330 | ||||||||

1R2 | 1.2 | 6R2 | 6.2 | 470 | 47 | 361 | 360 | ||||||||

1R3 | 1.3 | 6R8 | 6.8 | 510 | 51 | 391 | 390 | ||||||||

1R4 | 1.4 | 7R5 | 7.5 | 560 | 56 | 431 | 430 | ||||||||

1R5 | 1.5 | 8R2 | 8.2 | 620 | 62 | 471 | 470 | ||||||||

1R6 | 1.6 | 9R1 | 9.1 | B C J K | 680 | 68 | 511 | 510 | 100V | ||||||

1R7 | 1.7 | 100 | 10 | 750 | 75 | 561 | 560 | ||||||||

1R8 | 1.8 | 110 | 11 | 820 | 82 | 621 | 620 | ||||||||

1R9 | 1.9 | 120 | 12 | 910 | 91 | 681 | 680 | 50V | |||||||

2R0 | 2.0 | 130 | 13 | F | 101 | 100 | 751 | 750 | |||||||

2R1 | 2.1 | 150 | 15 | 111 | 110 | 300V | 821 | 820 | |||||||

2R2 | 2.2 | 160 | 16 | 121 | 120 | 911 | 910 | ||||||||

2R4 | 2.4 | 180 | 18 | 131 | 130 | 102 | 1000 | ||||||||

2R7 | 2.7 | 200 | 20 | 151 | 150 | ||||||||||

3R0 | 3.0 | 220 | 22 | 161 | 160 | ||||||||||

Performance

Item | Specifications |

Quality Factors(Q) | 2000 min. |

Insulation Resistance(IR) | 105 Megohms min. @ +25°C at rated WVDC. 104 Megohms min. @ +125°C at rated WVDC. |

Rated Voltage(WVDC) | see above tables |

Dielectric Withstanding Voltage (DWV) | 250% of rated Voltage for 5 seconds. |

Operating Temperature Range | -55℃ to +125℃ |

Temperature Coefficient(TC) | 0±30ppm/℃ |

Capacitance Drift | ±0.02% or ±0.02pF, whichever is greater. |

Piezoelectric Effects | None |

Environmental Tests

Item | Specifications | Method |

Terminal Adhesion | Temrination should not pull off, Cemera should remain undamaged | Linear pull force exerted on axial leads soldered to each terninal 2.0lbs |

Resistance to soldering heat | No mechanical damage Capacitance change:-1.0%~+2.0% Q>500 I.R.>10 G Ohms breakdown voltage:2.5 X WVDC | Preheat device to 150°C-180°C for 60sec DIP in 260°C±5°C solder for 10±1 sec.Measure after 24±2 hours cooling period |

Thermal Shock | No mechanical damage Capacitance change:±5% or 0.5pF max Q>500 I.R.>10 G ohms breakdown voltage:2.5 X WVDC | MIL-STD-202, Method 107, Condition A. At the maximum rated temperature(-55℃ and 125℃) stay 30 minutes.The time of removing shall be not more than 3 minutes. Perform the five cycles. |

Humidity (steady state) | No mechanical damage Capacitance change:±5% or 0.5pF max Q>300 I.R.>10 Gohms breakdown voltage:2.5 X WVDC | MIL-STD-202.Method 106 |

Low voltage hummidity | No mechanical damage Capacitance change:±3% or 0.3pF max Q>300 I.R.>10 G ohms breakdown voltage:2.5 X WVDC | MIL-STD-202, Method 103, Condition A, with 1.5 Volts D.C. applied while subjected to an environment of 85°C with 85% relative humidity for 240 hours min. |

Life | No mechanical damage Capacitance change:±2% or 0.5pF max Q>500 I.R.>10 G ohms breakdown voltage:2.5 X WVDC | MIL-STD-202, Method 108, for 1000 hours, at 125℃. 200% Rated voltage D.C. applied. |

YXC75B Chip Dimension

Item | length | width | thickness |

Chip Dimension | 0.080 (2.0) | 0.050(1.20) | 0.057(1.45) |

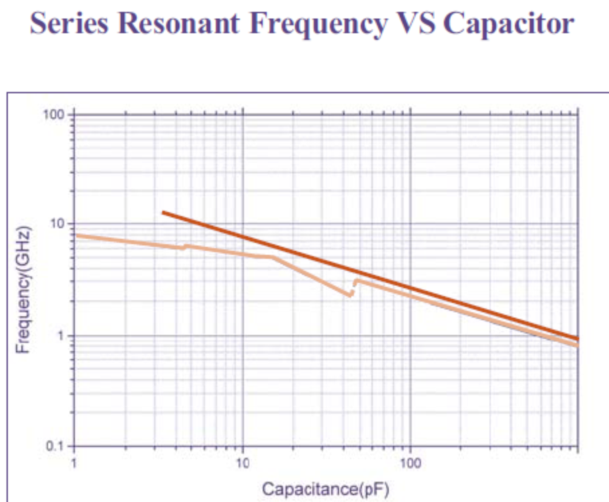

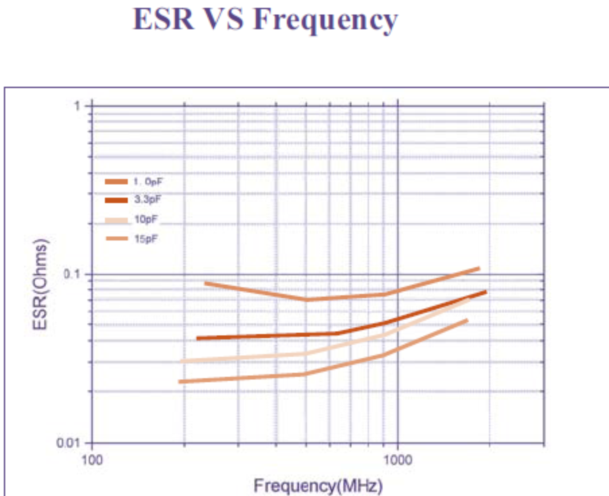

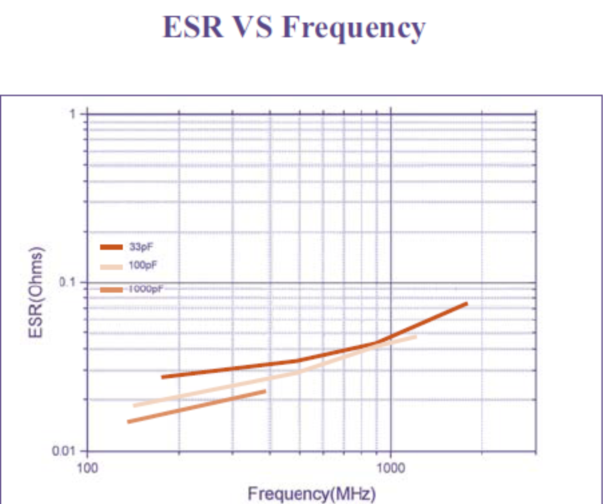

YXC75B Performance Curve

YXC75B Performance Curve